Pumps, Valves & Mixers

Request QuoteIndustrial Pumps

Ultimate Performance

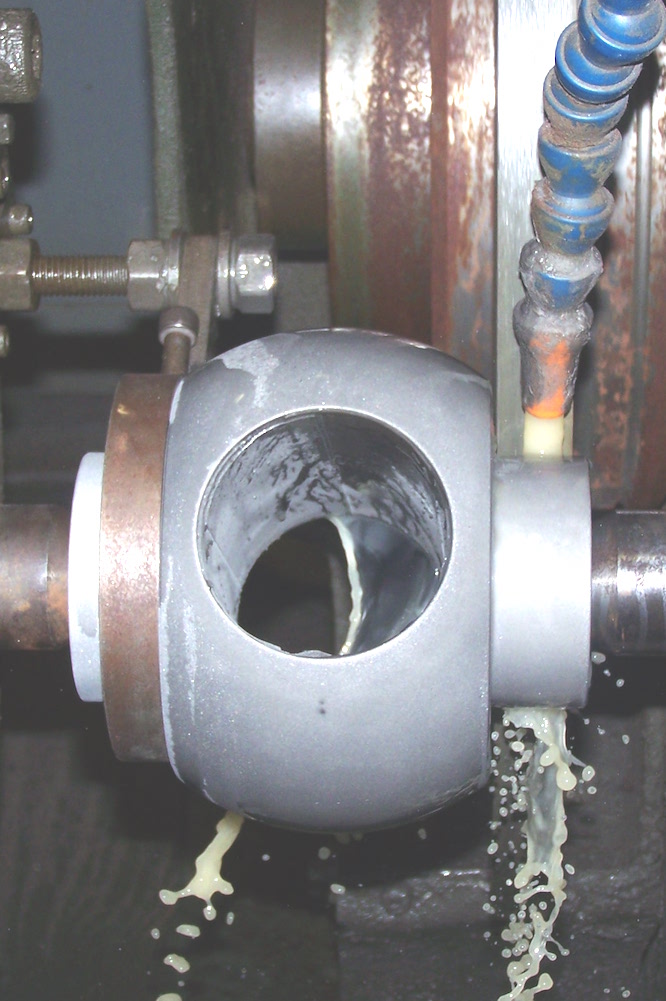

Cincinnati Thermal Spray has been providing services for industrial pumps for over 25 years including Centrifugal, Reciprocating, and Slurry pumps. CTS can make parts complete such as wear rings, shafts, plungers, casings, sleeves, bushings and more.

Forces like friction, corrosion, abrasion, and more are a constant threat to industrial pump components. These forces derail production and result in costly downtime. CTS engineers are experts at analyzing complex problems and developing innovative coatings to achieve and maintain peak performance.

Pumps, Valves & Mixing Components

Stronger Parts Made to Move

With precision manufacturing capabilities and groundbreaking thermal spray technologies, CTS is your one-stop-shop for coated components and parts.

Our innovative coating services bring your product and process’ performance levels to new heights, delivering comprehensive, industry-leading applications that resist and protect against deterioration caused by erosion, corrosion, friction, and heat. Coupled with our commitment to delivering quality applications, our industry-leading coating solutions have garnered praise from loyal clients across the nation.

- Shafts

- Impeller Rings

- Case Rings

- Lantern Rings

- Stuffing Box Bushings

- Shaft sleeves

- Hard-faced Bearings

- Throttle Bushing

- Center Bushing

- Diaphragms

- Inducers

- Stems

- Seats

- Balls

- Valve Bodies

- Tail Casings

- Nozzles

Coatings for Pumps

Title

Lorem ipsum sit amet dolor.

- Thermal spray

- Hvof

- Plasma transferred arc

- Spray and fuse

- Chrome oxide

- Colomonoy 5 & 6

- Hvof tungsten carbide

- Colbalt binder

- Stellite 1, 6 and 12

Manufacturing

Maintain Peak Performance

In the pump industry, forces like friction, corrosion, abrasion, and more constantly threaten deteriorating components, which can derail production and result in costly downtime. CTS engineers are experts at analyzing complex problems and developing innovative coatings to achieve and maintain peak performance for industrial pumps. CTS specializes in coating applications for the pump industry, including thermal spray, HVOF, Plasma Transferred Arc (PTA), and spray and fuse. Common coatings include Chrome Oxide, Colmonoy 5, Colomony 6, HVOF Tungsten Carbide with a cobalt binder (WC-Co), Stellite 1, Stellite 6, Stellite 12, and others.

- Shafts

- Impeller Rings

- Case Rings

- Lantern Rings

- Stuffing Box Bushings

- Shaft sleeves

- Hard-faced Bearings

- Throttle Bushing

- Center Bushing

- Diaphragms

- Inducers

- Stems

- Seats

- Balls

- Valve Bodies

- Tail Casings

- Nozzles

Our Markets

Innovative & Unique Coating Services

Every market we serve has a specific combination of products, parts, processes, and challenges.

Our technological expertise along with a thorough understanding of your industry’s complexities is critical to identifying existing and potential problems with your product or processes. We then leverage our research and collected industry data to create opportunities and custom coating solutions to improve your product’s overall performance.